Have you ever wondered what makes shaping, cutting, or polishing metal and other tough materials so precise and quick? The answer often lies in a tool called a grinder.

If you’re curious about how this powerful device works and why it might become your new best friend for DIY projects or professional tasks, you’re in the right place. By the end of this article, you’ll understand exactly what a grinder tool is, how it can make your work easier, and why it deserves a spot in your toolbox.

Ready to discover the secret behind smooth finishes and sharp edges? Let’s dive in.

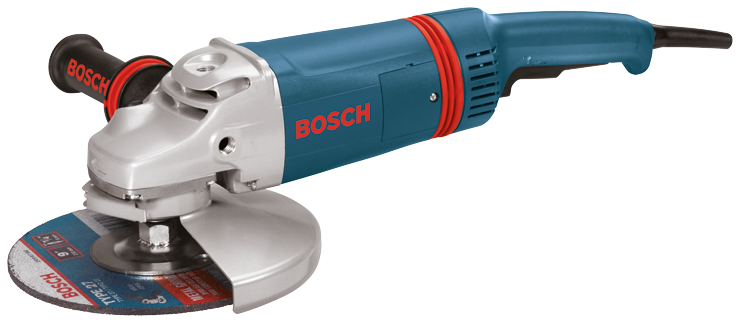

Credit: www.boschtools.com

Types Of Grinder Tools

Grinder tools are essential for shaping, sharpening, and polishing materials. They come in different types, each designed for specific tasks.

Understanding the different types helps you choose the right tool for your project.

Angle Grinders

Angle grinders are handheld tools with a rotating disc. They cut, grind, and polish metal or stone surfaces. They are useful for heavy-duty jobs.

Bench Grinders

Bench grinders are stationary tools mounted on a workbench. They have two grinding wheels for sharpening and shaping tools. They are common in workshops.

- Sharpening blades

- Removing rust

- Shaping metal parts

Die Grinders

Die grinders are small, handheld tools with a rotating bit. They work well for detailed grinding, carving, and polishing in tight spaces.

Straight Grinders

Straight grinders have a straight body and are used for precise grinding tasks. They are popular in metal fabrication and automotive work.

| Feature | Use |

|---|---|

| Straight shape | Easy to handle in narrow areas |

| High speed | Efficient material removal |

| Varied attachments | Versatile for many jobs |

Common Uses Of Grinder Tools

Grinder tools are versatile machines used in many workshops and homes. They help shape, cut, and finish different materials. These tools work with metal, wood, and other hard surfaces.

This article explains the common uses of grinder tools in four main areas. Each use shows how grinders make work easier and more precise.

Cutting

Grinder tools cut through metal, tile, and concrete quickly. They use abrasive wheels or discs to slice materials with clean edges. This makes them useful in construction and metalwork.

- Cutting metal pipes and rods

- Trimming tiles for a perfect fit

- Shaping concrete edges

- Removing bolts and screws

Grinding And Sharpening

Grinding smooths rough surfaces and removes excess material. Sharpening uses the grinder to restore sharp edges on tools like knives and blades. This improves their cutting ability and safety.

| Task | Description |

| Grinding | Removes rust and smooths metal surfaces |

| Sharpening | Restores sharp edges on blades and tools |

| Deburring | Removes sharp edges after cutting |

Polishing And Buffing

Grinders polish metal and wood surfaces to make them shiny. Buffing removes scratches and gives a smooth finish. This is common in auto repair and furniture making.

Common polishing and buffing uses include:

- Polishing car bodies and chrome parts

- Buffing wooden furniture to a smooth finish

- Shining metal tools and kitchenware

Surface Preparation

Grinders prepare surfaces for painting or welding. They remove old paint, rust, and dirt. This helps new coatings stick better and lasts longer.

- Cleaning metal before welding

- Removing rust and corrosion

- Smoothing surfaces before painting

- Preparing concrete for coating

Materials Compatible With Grinders

Grinder tools are versatile machines used for cutting, grinding, and polishing. They work well on many materials. Knowing what materials you can use with a grinder helps you choose the right tool and accessories.

This guide explains common materials that grinders can handle. Each material needs specific types of discs or attachments for best results.

Metal

Grinders work great on metal surfaces. They can cut, shape, and smooth metals like steel, iron, and aluminum. Use grinding discs made for metal to avoid damage.

- Steel: common for construction and tools

- Iron: used in heavy machinery and parts

- Aluminum: lightweight and easy to grind

- Brass and copper: softer metals for special jobs

Wood

Grinders can shape and smooth wood with the right attachments. Sanding discs and flap wheels work well. Avoid using cutting discs made for metal on wood.

Stone And Concrete

Stone and concrete are tough materials. Grinders cut and polish them with diamond blades or grinding wheels. Use water to reduce dust and heat.

| Material | Recommended Disc Type | Common Uses |

|---|---|---|

| Concrete | Diamond blade | Floors, walls, driveways |

| Granite | Diamond grinding wheel | Countertops, monuments |

| Marble | Polishing pads | Decorative surfaces |

| Brick | Cutting disc | Building walls |

Plastic

Grinders can shape and smooth plastic materials. Use sanding discs with fine grit to avoid melting or cracking the plastic. Cut slowly for best results.

Tips for grinding plastic:

- Use low speed settings

- Choose fine sanding discs

- Keep the tool moving to avoid heat build-up

- Wear a mask to avoid inhaling plastic dust

Credit: www.amazon.ca

Choosing The Right Grinder

A grinder tool is useful for cutting, grinding, and polishing. Picking the right grinder helps you work safely and efficiently.

Different jobs need different grinders. Look at power, size, discs, and safety before buying.

Power And Speed

Power shows how strong the grinder is. Speed means how fast the disc spins. Both affect the work quality.

High power and speed suit tough materials. Low power is better for small or delicate jobs.

- Higher power for metal and concrete

- Lower power for wood and soft materials

- Variable speed helps control cutting depth

Size And Portability

Grinders come in many sizes. A smaller grinder is easier to carry and use in tight spaces.

Large grinders are heavier but handle bigger jobs fast. Choose size based on your work needs.

- Small grinders weigh less than 4 pounds

- Large grinders can weigh over 10 pounds

- Consider battery power for cordless use

Disc Types And Sizes

Discs do the cutting or grinding. Different discs fit different materials and tasks.

Disc size affects the depth and speed of the cut. Use the right disc for your grinder size.

- Grinding discs for removing material

- Cutting discs for slicing metal or stone

- Flap discs for smoothing surfaces

- Common disc sizes: 4.5, 5, and 7 inches

Safety Features

Safety is important when using grinders. Look for features that protect you during work.

Good safety features reduce accidents and help you control the tool better.

- Adjustable guards to block sparks and debris

- Anti-vibration handles for comfort

- Automatic shut-off in case of overload

- Lock-on switches to prevent accidental start

Benefits Of Using Grinder Tools

A grinder tool helps smooth, cut, and shape materials like metal and wood. It uses a rotating wheel or disc to perform these tasks.

Many workers choose grinder tools for their many advantages. These tools make jobs easier and faster to complete.

Efficiency And Speed

Grinder tools work quickly to remove unwanted material. They help finish tasks in less time than manual methods.

Using a grinder reduces the effort needed. This lets workers complete more jobs in a day.

Versatility

Grinder tools can be used on many materials. They work on metal, wood, plastic, and stone.

Different attachments and discs make grinders suitable for cutting, polishing, or grinding. This makes them useful for many tasks.

Precision And Control

Grinders allow users to work with detail and accuracy. Small wheels and adjustable speeds help control the work.

This control reduces mistakes and improves the quality of the finished product.

Cost-effectiveness

Grinder tools save money by speeding up work and reducing waste. They lower the cost of materials and labor.

Many types of grinders are affordable and last a long time. This makes them a smart choice for many users.

Safety Tips For Grinder Use

Grinder tools are powerful and useful for cutting, grinding, and polishing. Safe operation is crucial to prevent injuries.

Follow these safety tips to ensure a safe experience when using a grinder tool.

Protective Gear

Wearing the right protective gear is essential for grinder safety.

- Wear safety goggles to protect your eyes.

- Use gloves to safeguard your hands.

- Put on ear protection to reduce noise exposure.

- Wear a dust mask to avoid inhaling particles.

Proper Handling

Proper handling of the grinder tool minimizes risks.

Always hold the grinder firmly with both hands. Ensure a stable posture to maintain control. Do not force the tool; let it operate at its own pace.

Maintenance And Inspection

Regular maintenance and inspection keep the grinder in good condition.

| Check | Frequency |

| Inspect the wheel for damage | Before each use |

| Clean the vents | Weekly |

| Lubricate moving parts | Monthly |

Avoiding Common Hazards

Be aware of common hazards to prevent accidents.

Credit: www.homehardware.ca

Frequently Asked Questions

What Is A Grinder Tool Used For?

A grinder tool is used to cut, grind, and polish materials like metal, stone, and wood. It helps shape surfaces and remove excess material efficiently, making it essential in construction, metalwork, and DIY projects.

How Does A Grinder Tool Work?

A grinder tool uses a rotating abrasive wheel or disc to wear down surfaces. The high-speed rotation grinds, cuts, or smooths materials quickly. Different attachments allow for various functions like cutting, grinding, or sanding.

What Types Of Grinder Tools Are Available?

Common types include angle grinders, bench grinders, and die grinders. Each type serves specific tasks, from heavy-duty cutting to precision grinding. Choosing the right grinder depends on your project needs and material type.

Is A Grinder Tool Safe To Use?

Yes, if used correctly with safety gear like gloves and goggles. Always follow manufacturer instructions, keep the tool steady, and avoid loose clothing. Proper handling minimizes risks like sparks, debris, or accidental cuts.

Conclusion

A grinder tool helps cut, shape, and smooth many materials. It works fast and saves effort on tough jobs. You can use it for metal, wood, and stone tasks. Different types fit different needs and projects. Always follow safety rules when using a grinder.

Knowing how it works makes your work easier and better. A grinder tool is a useful addition to any toolkit. It brings power and precision to many DIY and professional jobs.